Evolution of Lotion Pumps

Time: 2019-06-14 17:07:50

After decades of development, pumps have penetrated into every aspect of daily life. Moreover, the function, appearance, and practicability have been greatly improved. The following is a brief introduction to the development history, working principle, and inspection standards of various pumps.

History of Pumps

According to available historical records, this type of dispenser was widely used in China as far back as 500 years ago in the 14th year of Ming Zhengtong (AD 1449), and it was called "water dragon" at that time.

"Water dragon" is a common name for fire extinguishers in the old days: it consists of a wooden barrel about 0.8 meters high, 0.8 meters wide, and 1 meter long, several secondary buckets, water belts, spray gun heads and other facilities. A well-shaped wooden pad is installed at the bottom of the barrel to facilitate the placement of the faucet. Two pumps made of copper are placed side by side in a large wooden barrel. There is a piston in the pump that can move up and down. There are water inlet and outlet valves inside. The piston is connected to the upper lever. Press the lever to spray water. Two movable iron ring handles are installed on the left and right sides of the bucket wall, which is convenient for two people to lift the water dragon when saving water, and the other two use one hand to assist with the handle, so as to reduce the load of the water dragon lifter, speed up the running speed, and strive for rescue. water time.

The comparison of the development process of Chinese and foreign modern history is also reflected in the development of the dispenser. Industrial production and consumer demand have brought about the vigorous development of dispensers in Europe and America. The earliest rise is the valve.

The concept of the aerosol valve originated in 1790 with the launch of a pressurized carbonated drink in France.

In 1837, a man named Perpigna invented an aerosol bottle filled with soda.

In 1899, inventors Herlbling and Pertsch patented the first aerosol cans in history to use methyl and ethyl chloride as propellants.

In 1930, the cosmetics giant L’Oreal in France invented Lotion (emulsion). But it is not as convenient to use as a lotion pump, and the lids (Qianqi lids, butterfly lids, and even aluminum cans) are commonly used. Today, there are quite a few markets in Europe and the United States that use caps for large-package shampoos and shower gels. Especially the reasons: one is traditional usage habits, and the other is environmental protection.

In 1966, an eighth-grade student in Quebec, Canada, used a ballpoint pen and a tube in a science experiment class to invent our original lotion pump. At that time, a large hand sanitizer company used this design to develop a lotion pump head that could be mass-produced (and respected, without applying for a patent), which is the prototype of the pump head structure that we often see today.

In 1996, a company in Europe and the United States filed a lawsuit because of the water ingress problem caused by the design defect of the lotion pump head used in baby products. Three companies around the world set out to invent the anti-water pump head that has been leading the trend for decades. Lotion pumps enter a new era.

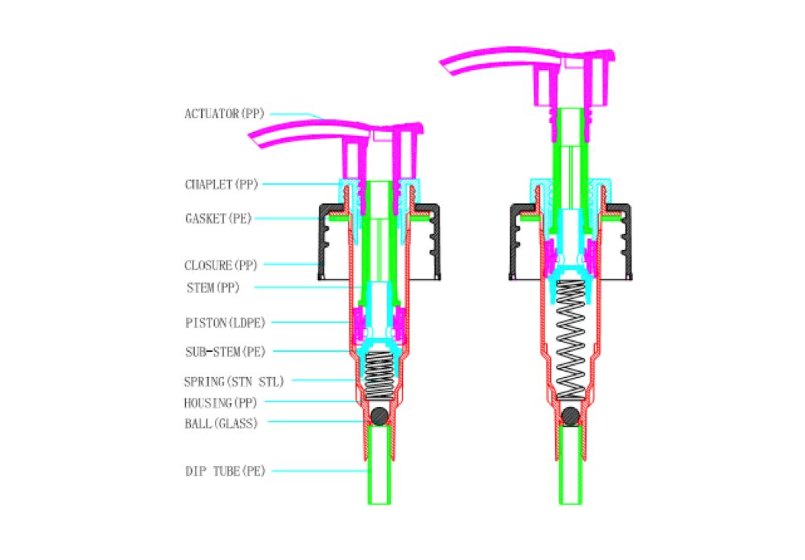

How Lotion Pumps Work

When the ACTUATOR is pressed for the first time, the ball valve (BALL) and the body (HOUSING) are closed, and the gas sealed in the body is forced to be discharged from the sub-post (SUB-STEM) hole through the nozzle;

When the push head bounces, the piston (PISTON) and the auxiliary column are in a sealed state, and they continue to rise under the force of the spring (SPRING), forming a sub-vacuum state in the body to generate suction, and the liquid will pass through the suction tube (DIP TUBE ), the ball valve and enter the body;

When the push head is pressed again, the ball valve and the body are closed, and the liquid in the body is squeezed, and will be forced to be discharged from the auxiliary column hole through the head nozzle!

Testing and Quality Control

1. Tightness: Fill the bottle with colored water (or customer liquid) according to the product specifications, use the corresponding torque according to different calibers to match the pump head with the bottle, press the head in a locked state, place it horizontally, and vacuum test- 0.03~-0.06MPa/5min (different customer requirements are inconsistent). After the test, there is no leakage at the joint between the bottle and the thread, the joint between the body and the lock cap and the press head.

2. After the press head is matched with the main column, the separation force between the press head and the main column must generally be able to bear the weight of the entire package. General parameters can be qualified with not less than 2Kgf.

3. Air pressure times/first spray times. It refers to the total number of times the consumer presses the button from when the button is opened to when the liquid is discharged for the first time. The commonly used standard is 6~10 times.

4. Pumping volume: refers to the volume of liquid pumped out by consumers each time they use the lotion pump. The usual tolerance of the pump output is about ±10% of the theoretical design value.

5. The opening torque between the press head and the lock cover is 3-10Kgf. cm.

6. Drop test: cooperate with the corresponding bottle, fill the liquid (or water) of standard weight, drop it vertically on the concrete floor once at a height of 0.8~1.2 meters, the bottle touches the ground first, and the product is qualified if it is not broken or loose. (Note: Only when the material is changed or the formula is changed, and the new mold is mass-produced for the first time, this test is carried out on the product).

7. Pump feel: good rebound, no sluggish phenomenon, rebound time ≤ 1.5 seconds, fatigue test after pressing ≥ 2000 times, the rebound must be normal.

8. The tightness between the straw and the body should be moderate, not too loose (easy to fall off) or too tight (easy to cause the body to burst). The general parameters can be qualified as not less than 0.5Kgf (products with different hose specifications need to be re-evaluated).

9. The thread fits smoothly with the mouth of the bottle, without slipping, blocking, and skewing.

Use Case Analysis and Outlook

Lotion pump products are widely used in cosmetic, hairdressing and washing products and other daily chemicals, cosmetics and medical product packaging. Huge and in high demand.

Since entering the 21st century, China's daily chemical and packaging industries are facing unprecedented opportunities for development. The packaging industry of daily chemical products is also developing into an emerging industry with continuous technological progress, increasing added value and more considerable scale!